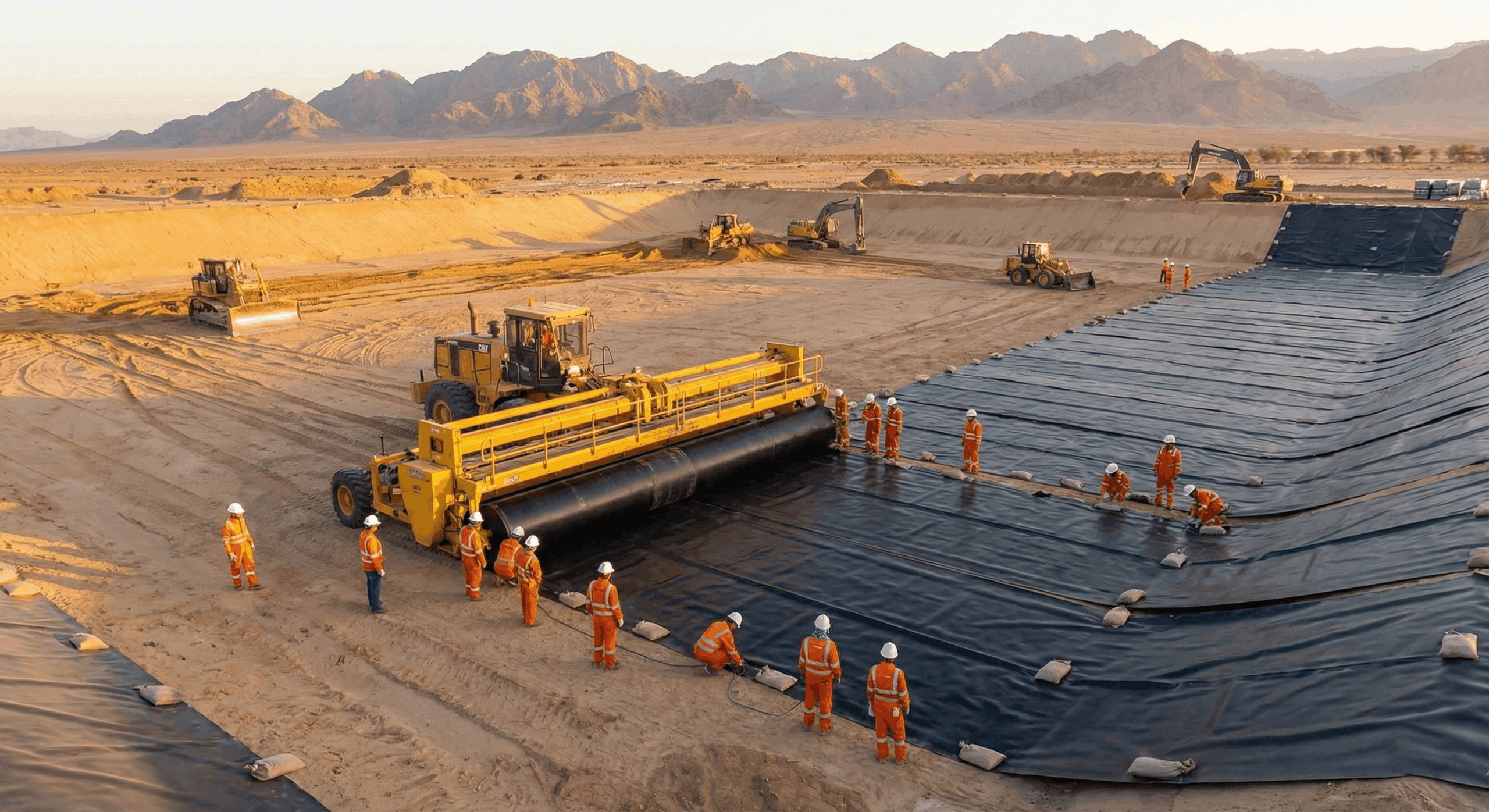

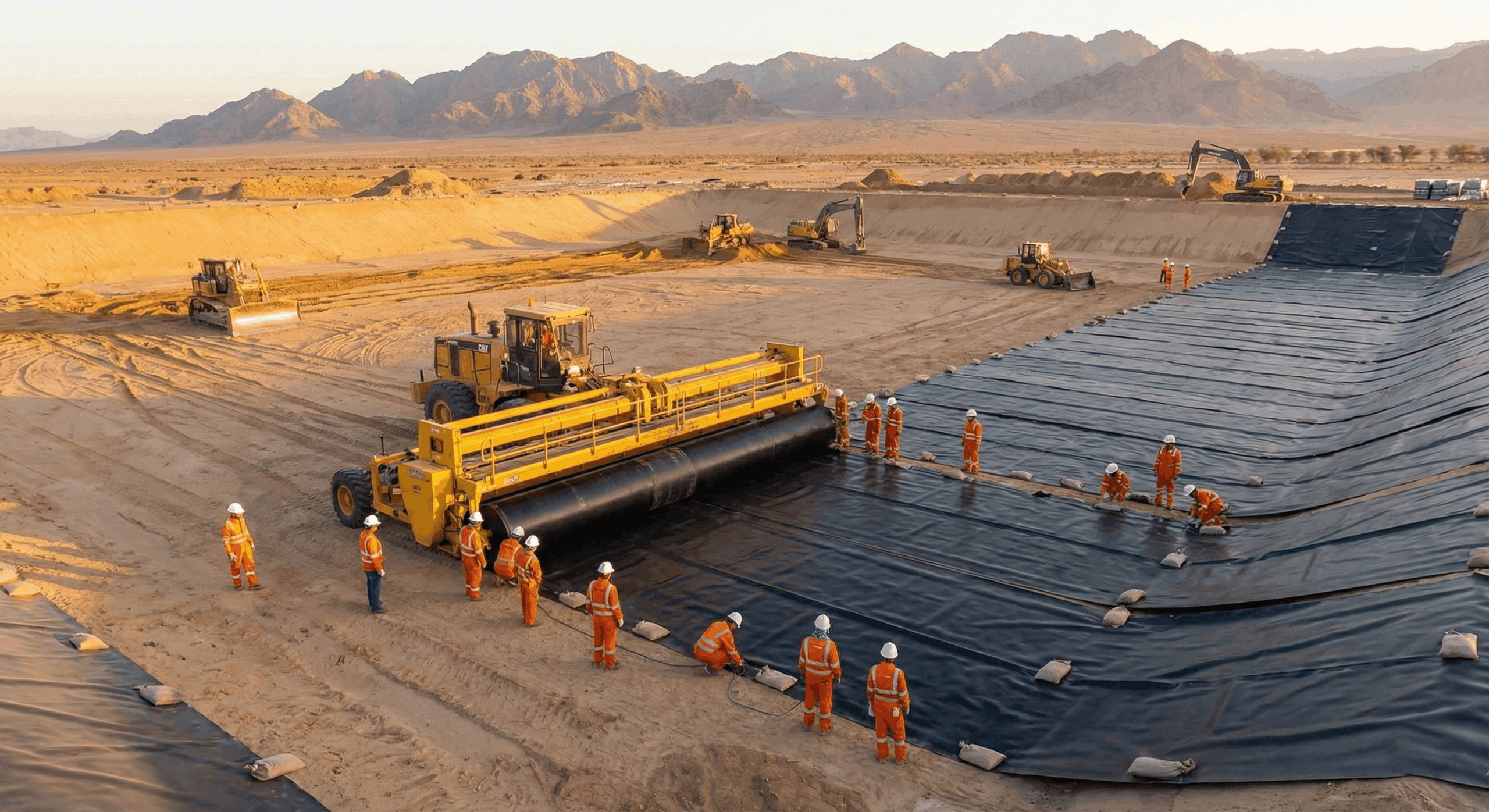

As manufacturers of high-density polyethylene and low-density polyethylene insulation boards and floor linings used in multiple sites and projects around the world, we have considerable experience and significant technical knowledge in our field.

High-Density Polyethylene (HDPE) insulation is considered one of the most efficient and widely used insulation and lining solutions in modern infrastructure and construction projects. This is due to its high mechanical strength and excellent resistance to moisture and harsh environmental conditions. At UPI – United Plastic Industries, we provide customized HDPE insulation solutions designed to protect foundations, floors, and sensitive structural layers, while adhering to the highest standards of quality and sustainability. This ensures a longer service life for structures and reduces long-term maintenance costs.

High resistance to water and moisture penetration, making it ideal for insulating foundations and concrete slabs.

Smooth surface that facilitates installation and welding processes, ensuring a uniform insulation layer without voids.

Excellent tensile strength capable of withstanding structural loads and soil pressure.

Effective resistance to salts and chemicals present in soil and groundwater.

High dimensional stability that prevents unwanted shrinkage or expansion over time.

Suitable for residential, commercial, and industrial projects.

Modern textured surface that enhances bonding strength between the insulation layer and concrete.

Reduces the risk of slipping or movement during or after concrete pouring.

Excellent performance in areas exposed to high groundwater pressure.

Higher resistance to puncture and tearing compared to smooth surfaces under harsh conditions.

Ideal for heavy infrastructure projects such as tunnels, tanks, and retaining walls.

Contributes to improving the overall performance and long-term efficiency of the insulation system.

Locally manufactured under strict quality standards to ensure consistent performance and reliability.

Carefully selected high-density polyethylene raw materials to achieve optimal insulation properties.

Availability of both types (smooth and modern textured) to meet diverse project requirements.

Full compatibility with modern insulation systems used in the Egyptian and regional markets.

Technical support and industrial expertise to help you choose the most suitable solution for your project.

Certified warranty against manufacturing defects in accordance with recommended usage and storage conditions.

At UPI, we believe that proper insulation is the foundation of any successful project. Contact us today to obtain reliable HDPE insulation solutions that protect your investments and give you peace of mind. Let our team help you select the most suitable product for your project with the highest quality and best performance.

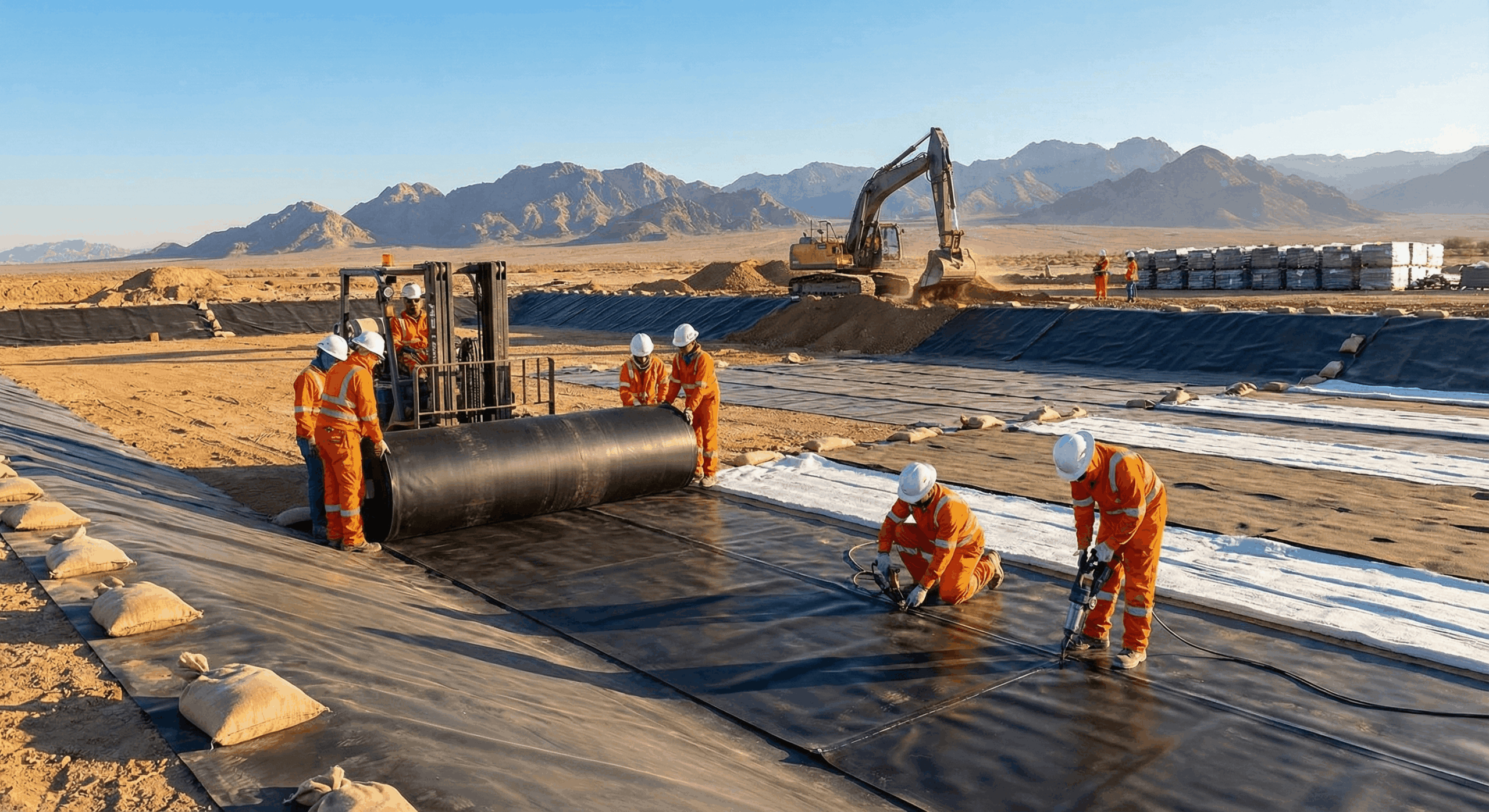

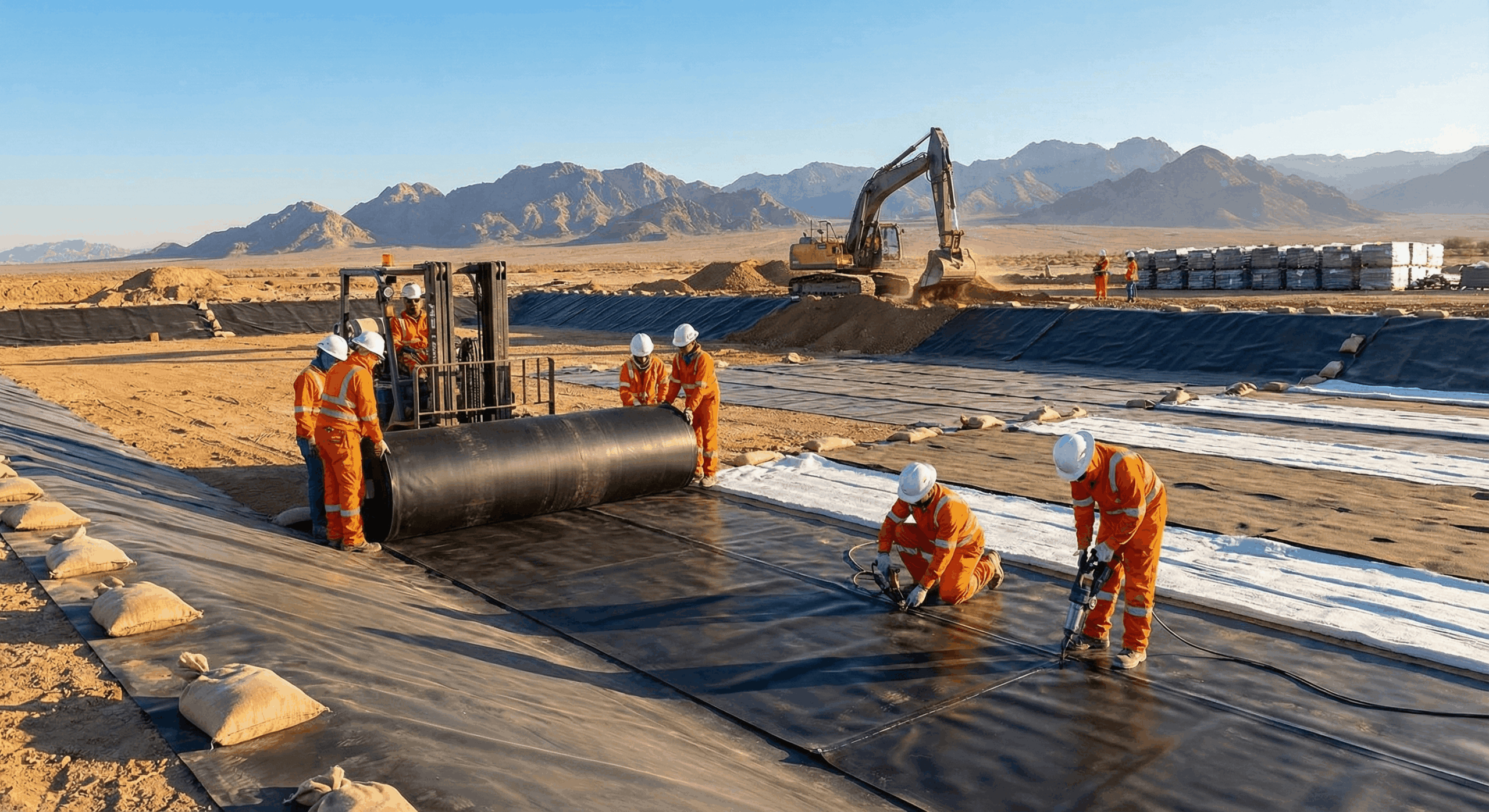

Low-Density Polyethylene (LDPE) insulation is considered one of the most practical and flexible solutions widely used in insulation and lining applications, especially in projects that require high flexibility and ease of installation. This type of insulation is distinguished by its excellent ability to adapt to various surfaces and curves, making it an ideal choice for insulating floors, walls, and light to medium insulation works in residential and commercial buildings. At UPI, we also provide LDPE insulation in both smooth and modern textured (embossed) types, offering reliable solutions that combine good performance with cost efficiency.

High flexibility that allows adaptation to different surfaces without cracking or damage.

Effective resistance to moisture and water vapor rising from the soil.

Smooth surface that facilitates fast and efficient spreading and installation.

Lightweight, reducing transportation effort and on-site installation work.

Helps protect concrete layers and finishing materials from moisture effects.

Suitable for use in floors, walls, and insulation works beneath slabs.

Textured surface that enhances bonding between the insulation layer and concrete or building materials.

Reduces the likelihood of insulation layer slippage during pouring or installation.

Better performance in areas that require additional stability of the insulation layer.

Improved resistance to tearing compared to smooth surfaces under harsh working conditions.

Suitable for projects that require economical insulation with a higher level of safety.

Contributes to improving the overall efficiency of the insulation system without a significant increase in cost.

Manufactured according to precise specifications to ensure consistent quality and reliable performance.

Availability of two types (smooth and modern textured) to cover various project requirements.

Cost-effective insulation solutions suitable for residential and commercial projects.

Easy installation that reduces execution time and labor costs.

Long industrial experience ensuring product compatibility with local market requirements.

Commitment to quality standards and a warranty against manufacturing defects under recommended usage conditions.

Choosing the right insulation is a fundamental step in protecting any structure. At UPI, we provide flexible and practical LDPE insulation solutions that meet your project needs with efficient performance and controlled cost. Contact us now, and let our team help you select the best insulation type that delivers high performance and long-term durability.

We will respond to your inquiry as soon as possible. We are always happy to serve our clients and partners in success.